ROTSE-III hardware manual

Version 1.0 08-Apr-2008 mcba, added info on Dec

encoder replacement,

collimation of the secondary mirror (including

focus model comments from Fang Yuan), and

a quick guide to some aspects of "rush"

Version 0.9 04-Feb-2006 mcba, added info/photos of the new cam3a

computer

Version 0.8 25-May-2005 mcba, added photos of the CCD camera boards

Version 0.7 18-Jan-2005 mcba, added Vaisalla precipitation detector

information

Version 0.6 29-Oct-2004 mcba, added oscilloscope traces for the gold box

Version 0.5 24-Sep-2004 mcba, lots of additions, particularly the servo

slipping/oscillation detection software

Version 0.4 28-Oct-2003 mcba, added links to images of ROTSE-IIIa

cable routing.

Version 0.3 07-Oct-2003 mcba, added fix for oscillation when homing.

Version 0.2 08-Aug-2003 mcba, added optical collimation section.

Version 0.1 05-Aug-2003 Michael Ashley, assisted by wisdom extracted

from e-mails by Alan Schier, Carl Akerlof, Eli Rykoff, Andre Phillips.

and Jim Wren.

See also, Andre's

fault-log page

Checklist of known problems, and what you should do to protect your

mount/telescope

- A drive motor can overheat due to excessive current over a

prolonged period of time (>30 minutes?). The motor will partially

demagnetise due to the temperature, and will therefore have reduced

performance from then on, making it more likely to overheat in the

future. Solution: install a thermostatic cutout switch on the motor body; ensure I2t (current-squared times time,

i.e., heating) protection is enabled in the

mount software; check the balance of the telescope, and look for cable

snags.

- The

drive capstans can be shredded, and the capstan then grinds into the

drive wheel. Solution: install Andre's protection widgets, or similar

devices, on both RA and

DEC axes; replace the capstans; adjust the

preload

and servo coefficients

appropriately;

repair the damaged metal surfaces with gentle application of, e.g.,

Scotch-Brite (take great care not to damage the encoder tapes). See

also this additional information.

- Misshapen images out of focus. Solution:

consider reducing the tension on the primary

mirror retaining screws. Other possibilities are wind

vibration, servo oscillation or collimation errors.

- A "thump" is heard as the mount slews. Solution:

it is possible that the RA and/or Dec axes are loose, consider adjusting the preloads.

- The mount oscillates at low frequencies, or with an audible whine. Solution:

the servo coefficients may need

adjusting; the drive capstans may be worn; the capstan

preloads may need adjusting.

- The mount oscillates when homing at the home limit switch. Solution:

balance the telescope so that it is

slightly

biased towards the home limit.

- The Renishaw encoder shows orange or red on its status LEDs for

part or all of the sky, possibly leading to a position error being

flagged by the mount computer. Solution: adjust the

encoder position; clean the encoder tape; inspect the RA/Dec axes for loseness.

ROTSE-IIIa cable routing

Note: the green rope is critical to proper operation (i.e.,

minimal torque applied to the telescope throughout the entire range

in RA and Dec.

Click on the images for the full-resolution view.

Oscillation when homing the telescope

Alan and Eli have identified a situation where the (im)balance of the

telescope will degrade the homing accuracy of the axes.

The desirable situation is that each axis shows neutral balance or be

biased slightly toward the home limit switch when the axis approaches

the switch. If this is the case, the homing should be repeatable

to a few arcminutes.

The undesirable situation is when an axis is biased to fall away from

the switch as the axis approaches the switch. This will cause the

"rocking" oscillation at the limit switch that has been observed.

The phenomenon is rooted in how the drive amplifiers are enabled and

disabled when the limit switch is tripped, and it is hardwired in the

electronics. There's no other reasonable way around it except to

balance the axis.

Adjusting the drive capstan preloads

Alan: It is not too difficult to get the preload for the drive correct.

One tightens the preload screw until the capstan does not slip when the

axis experiences a significant disturbance (like being pushed by hand).

And then maybe a half turn more. The drive surface and capstan

should be reasonably clean, but need not be spotless.

Andre comments: when tensioning the RA capstan onto the drive wheel, I

find there's a narrow range of tensions between too little (capstan

skids) and too much.

The Dec drive seems to be less touchy about the

capstan<->drive-wheel tension.

Possible causes for shredding of the RA

and Dec drive capstans

- The mount computer is running, but the servo software is not

running.

- The brakes are applied.

- Excessive current to the motor, causing slipping.

- The capstan preload may be low enough that the drive slips under

the steady application of torque. Once large-scale slipping starts, the

drive can shred the capstans in a matter of seconds.

- Violent oscillation of the capstan due to inappropriate servo

coefficients, or a gradual change in the drive characteristics (e.g.,

once the capstans wear, the rate of wear is likely to increase).

Preventing damage of the drive following

capstan wear

If the rubber coatings are sufficiently damaged, the metal capstan can

make

contact with the drive wheel, and eat its way into it, causing

substantial damage. To prevent this, you can install Andre's protection

widgets. Here are some images of them

on the ROTSE-IIIa telescope (which uses a different RA motor to the

other telescopes). An alternative is to use a stop-screw next to the

preload spring (Alan is designing one for ROTSE-IIId, and Dmitry has

made one for ROTSE-IIIb).

Setting the mount servo

coefficients: Kp, Ki, Kd

The ROTSE motors are stabilised by a PID (proportional, integral,

differential) feedback loop. The three coefficients Kp, Ki, and Kd,

have

to be set appropriately in order for this loop to be stable under all

conditions. The position encoder is a Renishaw tape mounted on the axis

drive wheel. If anything changes in the mechanical part of the loop

(e.g., o-ring wear, bearing preload), then this can affect stability.

Here is a prescription for setting initial values for Kp, Ki, and Kd,

from Alan Schier:

- Note the existing parameters (Kp, Ki, Kd) so that you can restore

them if needed.

- Put 2 and 0.4 in the f and z box respectively in the "Calculate

Gains from Break Frequency and Damping" box and click the calculate

button.

- Copy the resulting Kd and Ki value to the servo parameters for

the axis of concern.

- Lower Kp for that axis to maybe half of its current value.

- With the servo running (axis in the "Stop" state, probably),

raise Kp as described previously. That is, perturb the axis while

raising Kp until the servo oscillates and then lower Kp until the

oscillation stops.

This will leave the servo in a reasonably robust state.

If you want to push the envelope and make the servo more "aggressive",

start rasing the break frequency value from 2 to 3 or 4, recalculate

the

values of Kd and Ki. (In this case there is nothing to gain by changing

the damping, z.) Copy the new values to the servo parameters and

then readjust Kp again. What you will find is that the servo

becomes "stiffer", and the range of acceptable Kp values will

narrow. That is, the range between where Kp is too low

(sub-audible low frequency servo oscillation) and too high (audible

oscillation) becomes smaller. Eventually the range disappers

altogether,

and you will not be able to make the axis stable by adjusting Kp.

When you do this, you are moving the roots around in the complex plane

of the chacteristic equation that describes the system dynamics.

Some root positions are better than others. Roots in the right

half of the complex plane are unstable. Roots in the left half

are

stable and have a continuum of performance characteristics ranging from

"twitchy" to "sluggish".

The break frequency and damping describe the position of a complex pair

of roots over which we have direct control. The other roots are

controlled less directly since they are determined by the mechanics of

the system. In a sense, Kp is our remaining handle on those roots.

A further note: beware if you start to adjust Kp, Ki, and Kd by

simply observing the perfomance of the axis and changing one or

another. The stable combinations of these three exists is a space

in which they are surrounded by combinations that are unstable.

In

particular, if you start with all of them near zero, you will have to

traverse unstable territory to get to anything that performs well at

all.

Here are some additional notes from Alan on adjusting Kp in the event

of mount oscillation:

- Lower the Kp gain by 60%. Push on the RA axis with

your hand and watch the resposne. The servo should still be

stable. The axis may have a sluggish response and recover with a

bit of overshoot. This is normal.

- Start raising the gain with the little up arrow at the right side

of the Kp box. The axis's response to a push will become faster

and the overshoot will decrease.

- Keep raising the gain and listen/feel for an oscillation to start

as you keep perturbing the axis with your hand.

- Once you get an oscillation, quit pushing on the axis and start

lowering the gain by clicking on teh down arrow until the oscillation

stops by itself. That's the right place to leave the gain.

Some general notes:

- If the capstan slips when you push on the axis, tighten the drive

preload.

- If the Kp gain is too low, the axis will oscillate with a low

(sub-sonic) frequency.

- If the Kp gain is too high, the axis will oscillate with a high

(audible) frequency.

- There's usually no need to fiddle with Ki or Kd. They set

the position of a couple poles in the transfer function, and those

shouldn't need changing. The same goes for the filter

coefficients, only more so.

Andre notes that a good way of getting a feel for the system is to grab

the tail of the motor shaft that protrudes from the rear of the servo

motor and twist it abruptly this way and that. Andre noted some slight

"springiness" in the capstan drive shaft, deriving from the

helical coils in the shaft coupler. These are the coils that Alan

has partially filled with modeling putty in order to reduce vibration.

The following table shows the coefficient values at the indicated dates

(note that ROTSE-IIIa has a different RA motor from the other sites).

See also the servo.ini section below.

|

Kp (RA/Dec)

|

Ki (RA/Dec) |

Kd (RA/Dec) |

ROTSE-IIIa at 2003 Aug 14

|

27.273 / 8.743

|

15.708 / 10.472

|

0.06 / 0.066

|

ROTSE-IIIb at 2003 Oct 30

|

15.408 / 8.744

|

10.472 / 10.472

|

0.066 / 0.066

|

| ROTSE-IIIc |

Eli?

|

Eli? |

Eli? |

| ROTSE-IIId |

?

|

?

|

?

|

The server loop runs with a 2millisec period on a Windows NT computer.

The period can be varied in the servo.ini file, but Alan Schier can't

think of a good reason to do so. He comments "it can run as fast as 1

ms, but the low-frequency dynamics of the controller become numerically

sensitive at that point."

Anti-slip and anti-oscillation software

Michael wrote some modifications to Alan's code to include slip and

oscillation detection. Eli got this working on ROTSE-IIIb, and the aim

is to have it working on all sites. The code involves some new

parameters in the servo.ini file. Here is how it works:

Slipping

Slipping is

regarded as occurring if the following two conditions are met: the

absolute value of the axis velocity is less than a user specified value

(m_fAxis1SlipVelocityThreshold), and the absolute value of the axis

output voltage is greater than a user specified value

(m_fAxis1SlipVoutThreshold), i.e., we are driving the axis motor, but

the final shaft isn't moving. If these conditions occur for

m_fAxis1SlipCountThreshold consecutive servo cycles, then a slip fault

is set.

To establish values for the parameters, begin by deciding the maximum

time in seconds you can tolerate a slipping condition. This might be

0.3 seconds. Then set m_fAxis1SlipCountThreshold to this time divided

by the servo period (normally 2 milliseconds), e.g., 150. Now choose

the velocity (in encoder counts per servo cycle (I think)) below which

the shaft is regarded as being almost stationary; for guidance, the

fast home speed is about 75000, the slow home speed is about 1000; so

perhaps a value of 1000 is essentially stationary. Now choose the

output voltage threshold, m_fAxis1SlipVoutThreshold, above which it is

assumed that the shaft should be turning, this value should be greater

than any holding torque.

Actually, it might be best to measure the real performance of the

mount, and try to set parameters which will detect any obvious

deterioration in the performance.

To disable the slippage detection for the RA axis, set

m_fAxis1SlipCountThreshold to zero in the servo.ini file. For Dec,

change the 1 to a 2.

Oscillation

The test for oscillation is

based purely on examining the time behaviour of the axis output

voltage. The peak-to-peak amplitude of the voltage is determined over

an interval of m_nAxis1OscillationMaxCount servo cycles. This amplitude

is then squared and added to a decaying sum of all the previous

amplitudes squared. If this decaying sum exceeds the critical number

m_fAxis1OscillationFaultThreshold, then a fault condition is set.

In order to detect oscillation at a variety of frequencies, the

calculation is done over NUMFREQ different numbers of servo cycles. For

each frequency the user has to specify the following parameters:

m_nAxis1OscillationMaxCount[i] - the number of servo cycles over which

to calculate the amplitude. If this is zero, the calculation is skipped.

m_fAxis1OscillationDecay[i] - the decay constant to apply to the sum of

amplitudes

squared.

m_fAxis1OscillationFaultThreshold[i] - the threshold at which a fault

condition is set.

To disable the oscillation detection for the RA axis, set

m_fAxis1OscillationMaxCount[i] (for i equals 0 to 4) to zero in the

servo.ini file. For Dec, change the 1 to a 2.

Servo.ini files

The mount computer software reads a file called servo.ini when it

starts. This sets various parameters. Here is servo.ini for ROTSE-IIIa at 2005 Sep 30

And here is servo.ini for ROTSE-IIIb on

2004 Mar 18.

Measured axis torques

Andre says on 2003 Jan 15 (prior to the installation of a smaller RA

capstan): I made some measurements by applying measured torque to the

RA/Dec axes and comparing this with the servo correction voltage (as

displayed on the GUI). Using a small set of 'fisherman's' scales

I tugged at the telescope from different directions with different

forces and was pleased to note that the results were fairly

consistent. That is, for the RA axis, the servo correction

voltage is around 1.7V/pound.foot (+/-10%) = 1.3V/N.m. For

interest, the detente torque (RA motor engaged, power off) is ~2.1

pound.foot.

Out of interest I compared this with the response of the Dec motor and

got 0.8V/pound.foot (+/-10%) = 0.6V/N.m ; about half the RA

figure...which is interesting as it explains why it's so easy to go

overvolts on the RA and not the Dec. Dec detente torque is ~2.5

pound.foot.

Note that the above voltages are "as displayed on the GUI", not "as

applied to the motor". At the RA motor, the real voltage and current

torque figures are 0.4V/pound.foot and 1.1A/pound.foot.

The meaning of the GUI voltage reading

The voltage you see on the screen for the servo control is not the

voltage that is applied to the motor. It is the voltage that is

applied to the drive amplifier. The amplifier turns that voltage

into a current that ranges between +/-6 amps, which is what is then

applied to the motor. For the ROTSE-IIIa RA motor the ratio of the Vgui

voltage, versus actual measured motor terminal voltage is around 3

(+/-15%).

Motor specifications

The ROTSE-IIIa RA motor is a GPM16LR pancake motor

(http://www.pmlflightlink.com/gpseriesfrms.html). These specifications

also show that the continuous-stall current for this motor is an

impressive 8amps, or a terminal voltage of ~3.4V.

Mount limit switches

If the telescope reaches the first limit, the drive amplifier is

inhibited from driving further into the limit. It can still drive

out of the limit. If this isn't working, something's amiss in the

electronics.

Renishaw encoder

The specification for the RGH22-Y30D00 encoder head is for a maximum

runout of +/-0.1 mm, which is comfortably greater than the measured

runout of the ROTSE-III mounts. See the Renishaw

RGH22 data sheet, the installation

guide, and the DXF

drawing, for more information on the encoder.

The encoder head is sensitive to the yaw angle relative to the scale,

and less sensitive to the pitch and roll angles. If the yaw angle

is off, the encoder will not tolerate the full +/-0.1 mm range of

runout. If the light is turning red in places, move the axis just

to the edge of the red zone (the light may be orange) and poke the

encoder mount with your finger in the yaw direction. If you can

make the light turn green, that means the yaw angle could be

improved. For that matter, you can poke the mount in the other

directions as well to see if other adjustments would help.

Andre remarks: most of today I've been fiddling with the RA-axis

Renishaw encoder. I was mostly adjusting yaw and could get things

mostly right, but never consistently so. Then I decided that

guesswork was out and removed a lead weight and the lower aluminium

'bumper' bracket so that I could get vernier calipers around the sensor

and find out what was really going on. Thus exposed, it's

relatively easy to measure the yaw by measuring for parallelism of the

sensor with the overhead drive wheel. The correct 0.8mm spacing

from the graticule was achieved with a paper 'feeler gauge' (by a

convenient coincidence, our standard photocopy paper thickness is

0.10mm). Then I measured the roll (i.e. parallelism with the

tangent to the drive wheel) and was surprised to find it

off-by-a-country-mile (i.e. 2.3 degrees). This was corrected and... hey

presto... solid green status light all the time, no red/orange

flickering, no exceptions.

The moral of the story is that these encoders are very sensitive and

have to be set up precisely

to

spec, and trying to 'wing it' by simultaneously adjusting three

free-parameters is not the optimum way of doing it. Getting

down-and-dirty with measuring gear is the best method, even if it means

stripping the telescope down a bit to get the micrometer into

position.

The RA Renishaw encoder sits on an aluminium block heater. There is a

heater and thermocouple in that location. If you look at the

servo

control panel, you'll see the temperature monitoring/control info

toward

the lower left. The servo software monitors the temperature to

keep the block above 0 C (or whatever setpoint is set in the control

panel). The encoder heads are specified to 0 C. Below that, the

LED output declines. If properly aligned, they will work below 0 C (to

-10 C at least). If the alignment is marginal, the status light

will turn red.

Right ascension bearing adjustment

There is a nut on the lower end of the RA axle that bears against a

wavespring and the brake wheel. These items bear against the

inner

race of the lower bearing and provide tension to keep the fork snug

against the inner race of the upper bearing.

The preload nut is the ring at the center of the brake wheel.

First loosen the 1/4-20 set screw on the hub of the brake wheel.

1/2 to 1 turn should be enough. Then tighten the nut until it is snug

using a spanner wrench or a couple of punches placed in the holes for

the spanner wrench. The bearings are hugely oversized for the

load

they carry, and there is little danger of overtightening.

When things are snug, you should notice an appreciable increase in the

friction when you rotate the RA axis. If the friction hasn't

increased, the upper bearing is probably still loose. You could

monitor the position of the RA drive wheel relative to the base using a

dial indicator. If the axle was loose, you will see the drive

wheel settle back toward the base when you tighten the nut. Once this

is

done, you can loosen it just a bit. About 30 degrees is fine.

This

allows the wavespring to expand a bit. You can then tighten the

set screw on the brake wheel, and that should be it.

The bearings are tapered rollers.

What should the maximum runout be on the RA drive wheel? Alan's

recollection of the ROTSE-IIIa mount is that it had no more than

+/-0.04

mm (+/-0.0015") of runout on the drive wheel. Alan measured another

mount and found it is within +/-0.02mm (+/-0.0075") except for near a

machining ding that is outside the encoder area. Including that

ding, it would be about about +/-0.04 mm.

Declination bearing adjustment

The bearings on the drive side of the dec axis are an opposed pair of

roller bearings and are preloaded with wave springs on the

inside.

The bearing on the other side is a single roller bearing on the outside

portion of the axle with a wave spring under the nut (on the outside).

If the bearings are loose, a "thump" might be heard as the axis settles

depending on the telescope position.

The way to adjust the bearing is:

- Loosen the non-drive side a bit. Two or three turns on the

nut should suffice.

- Tighten the drive side nut until you flatten the preloading wave

spring. You'll feel the tightening torque increase suddenly when this

happens.

- Back the drive side nut off about 1/8 turn.

- Tighten the non-drive side nut until the wave springs are

flattened. This may take considerably more torque that for the drive

side since the preload on this side is larger.

- Back off the non-drive side nut about 1/8 turn.

That's it. The bearings are oversized for the task and very

robust. There's no need to be particularly ginger when tightening the

nuts.

Andre commented: unlike the RA bearing adjustment, I can easily see the

Dec bear adjusting nuts and wave springs. On the motor-drive-side

I noted see that the wave spring was looking nearly fully squished, but

on the non-drive-side, somewhat less squished. So I progressively

tightened the non-drive-side adjustment, and after at about

half-a-turn,

the "thump" disappeared.

Motor protection

The servo motors can be driven with quite high voltages (>10V) for a

short amount of time (a minute or so) in order to produce large

accelerations. However, they can only withstand 2 or 3V continuously

before they will overheat (on a timescale of perhaps 30 minutes). The

mount control computer will register a fault condition if either a high

voltage is applied for more than a user-defined number of seconds, or

the integrated power to the motor (measured by integrating the current

squared) exceeds a user-defined threshold. To prevent the "High Output

I^2" fault, you need to ensure that the mount is carefully balanced and

that there is no excess friction from, for example, snagging cables.

Thermostatic protection of the servo motors

At ROTSE-IIIa we have installed thermostats on the RA and Dec motors to

provide a last line of defense against motor overheating (which has

burned out at least three motors in ROTSE-IIIa/b). The thermostat we

used is a normally-closed encapsulated type, with a setpoint of

50C. This image shows the

thermostat topped with a gob of heat conductive paste, and set into a

foam-plastic 'blanket'. This

image

shows the thermostat strapped onto the side of the motor, and connected

in series with it. These particular thermostats have a hysteresis

of around 10C, so if the thermostat is tripped, it will take some time

for the motor to become reconnected. Note that this addition

doesn't interfere with the removal of the Dec drive wheel cover.

Primary mirror cell adjustments

The radial restraint is via four rather broad arcs, although as a

practical matter, the contact will be localized to a region in the

center of the arcs as the arcs are relatively compliant. The arcs

bear on the rear of the mirror. The arc material and dimensions

are chosen such that the system is athermal for uniform

temperature--they are not spring loaded. After the mirror is

installed, the arcs are adjusted such that they are in contact with the

mirror and are left there. Should this arrangement ever put the

mirror into a bind, it would be apparent as astigmatism in the image.

The following image shows the primary mirror cell, with the mirror

itself removed. The four arcs bear on a machined lip on the back of the

mirror, and are adjusted radially by set screws (one for each arc).

This image below shows one of the primary mirror retaining screws,

which bears down on a plastic L-shaped bracket, which in turn contacts

the edge of the mirror. The back of the mirror rests on the small brown

plastic strip visible below the bracket. It is very important that the

spring is not completely compressed (since this will allow large forces

to be placed on the mirror). It is also important that the L-bracket

and

the brown strip are aligned, and that the mirror is resting on the

three

brown strips, else a torque will be applied to the mirror.

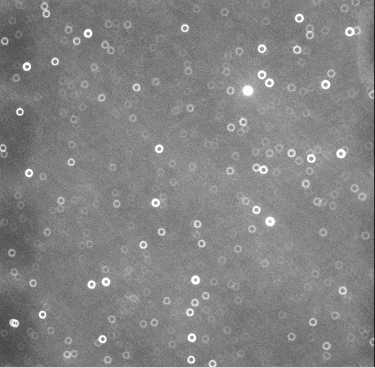

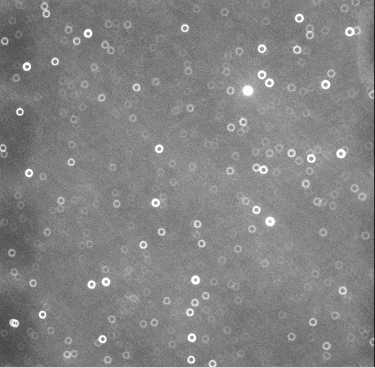

During the commissioning of ROTSE-IIIb the three primary mirror set

screws were too tight, turning the out-of-focus doughnuts into

triangles. Adjusting the set screws 1/128 turn past contact held

the mirror nicely without distorting the shape.

Metric/imperial?

Are you wondering why there is such a bewildering mix of metric and

imperial fasteners on that unit? It's because the telescope was

designed before there was a mount for it. It turns out that the

telescope was designed using metric dimensions. When we got a

mount, it was imperial. So, use metric wrenches

if you're working on the telescope; imperial for the mount.

Adjusting the secondary support vanes

It is possible to make the vanes tighter or looser, depending on how

the secondary assembly has been installed. To tighten the vanes:

- Loosen the both ends of the two vanes whose alignments do not

pass through the center of the secondary assembly. That is, there

is one vane that is strictly radial and two other that are a bit off of

radial. So, loosen the both ends of the two non-radial vanes.

- For each of those two vanes, slide the end nearest the secondary

cylinder in a direction tangential to the cylinder. There is a

bit

of clearance in the screw holes that will allow this. Q: Which

direction to slide them (clockwise or counter-clockwise)? A: In

the direction that would tend to pull the vane away from the outer

barrel.

- Tighten the screws that attach the vanes to the secondary

cylinder.

- Tighten the screws that attach the vanes to the outer

barrel. This should tension the vanes.

Collimation of the primary mirror and optics tower

The optical design of the ROTSE-III telescope employs a parabolic

primary mirror, a flat secondary, and a multi-element optical tower.

Aligning the secondary mirror is a trivial operation, since the fact

that it is flat means that the only necessary adjustments are two tilt

axes, and these can be easily done using out-of-focus star images.

Aligning the optical tower is much more difficult, since it has to be

both centred and tilted correctly with respect to the parabolic surface

of the primary, which is not necessarily aligned with the edges or back

of the mirror. Note that it is not necessary to align the optical axis

of the system with the telescope tube, or perpendicularly to the mirror

cell, although in practice any misalignment will probably be less than

1

degree in tilt and 1 mm in displacement.

In the following procedure, we assume that the internal elements in the

optical tower are correctly aligned.

Begin by taking the primary mirror cell and optical tower out of the

telescope. Insert a wooden block to hold the shutter open, as per the

following image.

Mount the mirror cell on a dividing head

from a milling machine (see the image below). The dividing head we used

had a central hole which enabled us to inject a laser beam via a 45

degree mirror. We used a portable hand-drill to assist with rotating

the

dividing head. The next task is to align the parabolic surface of the

primary mirror as exactly as possible with the rotation axis of the

dividing head. This can take a couple of hours of trial and error with

the crude setup we used. Sheets of paper were placed under the mirror

cell in order to make fine adjustments to the tilt. We bounced a laser

beam off the mirror surface and looked at the reflection on the wall of

the room, several metres from the mirror. When the beam does not move

when the dividing head is rotated, the mirror is perfectly aligned. We

were successful in aligning the tilt to < 1 arcminute, and the

centering to better than 0.2mm. The optical access of the ROTSE-IIIa

mirror is certainly within 0.5mm of the physical centre as defined by

the edges of the mirror.

Now shine a laser through the optical tower, using a mirror at 45

degrees positioned immediately below the dividing head. It is

relatively

easy to align the tilt and decentre of the laser precisely to the

optical access of the tower by looking at the reflections of the laser

light back along the optical path (the laser reflections on the various

lenses in the tower are visible in the image below). Now spend another

hour or so adjusting the tilt of the tower so that the reflected laser

light does not move when the dividing head is rotated. You may need to

machine an allan key in order to fit the four adjustment points on the

tower. Adjustment is performed by adding/removing plastic shims. We

were

able to achieve <1 arcminute alignment after some hours of work.

However, we noticed that the laser beam passing through the optical

tower wobbled by +/-2.5 arcminutes as the tower was rotated. We suspect

that this is due to some residual misalignment of the elements within

the tower.

Enclosure

The enclosure electrical diagram.

Vaisala humidity sensor

The trigger voltage is 2.90V ("dry" is around 2.95V).

I/O box

From Jim Wren: the relays are made by IDEC and claim to be fine for

general use at 7A for 240VAC (7.5 for 120VAC). I checked the spec

sheet for the Duff Norton linear actuators and they say they draw

6.2A@115VAC and 2.0A@220VAC for the max applied load which is

1500lbs. This should be well within what the relays can handle.

Camera problems

Bob Leach has received the ROTSE-3b TEC power supply, and has found the

problem: one of the two 6.5V switching power supplies burned off

its electrical contact. This problem has happened before.

Bob has a theory of "grit" getting in there, and has replaced the

offending switching power supply, and has improved the output

connector. However, we are not sure if this is a permanent fix,

or if there is some other problem with the power supply.

Focus motor

From the manufacturers specifications:

It may be necessary to lubricate the drive screw after approximately

500 hours of continuous use. A lint free wipe should be used if

removing spent or excess lubricant from the drive screw. A suitable

lubricant can be provided by Newport upon request. (Newport part number

CMA-LUBE).

Polyurethane capstans

We have 4-pcs 65-70 black and 4-pcs 75-80 blue. Both are high

strength polyurethane poly-ether base. Purchased from

metalrubber.earthlink.net

in March 2005.

Camera firmware

Checksum of the EEPROM in the timing board is B68D.

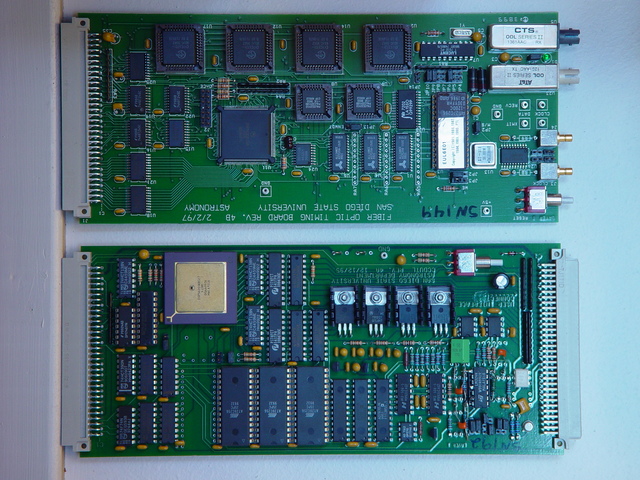

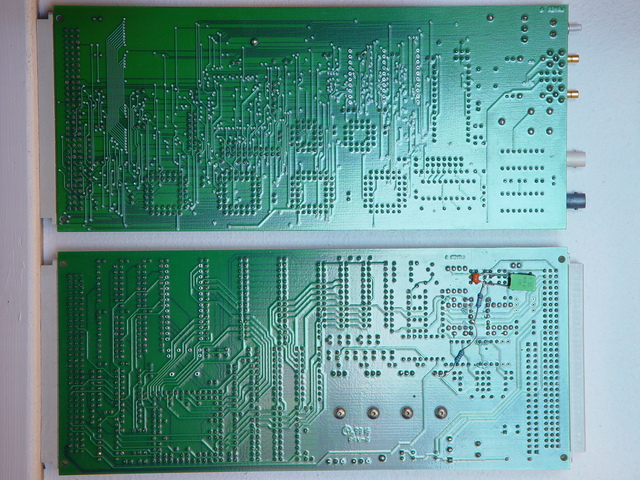

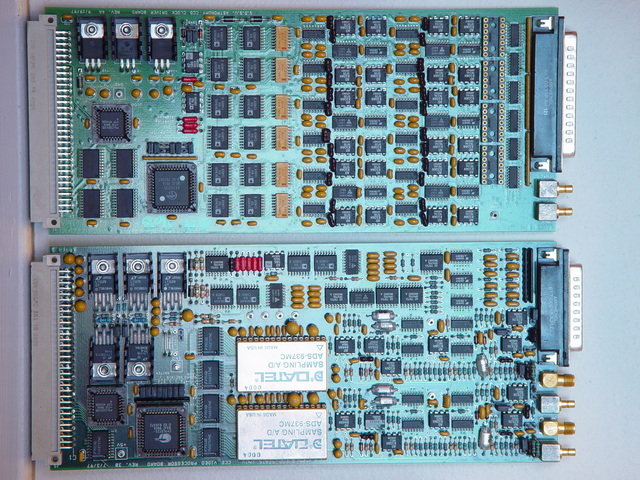

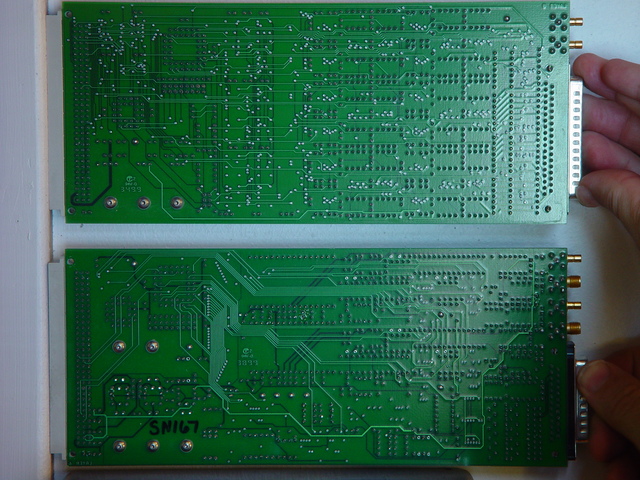

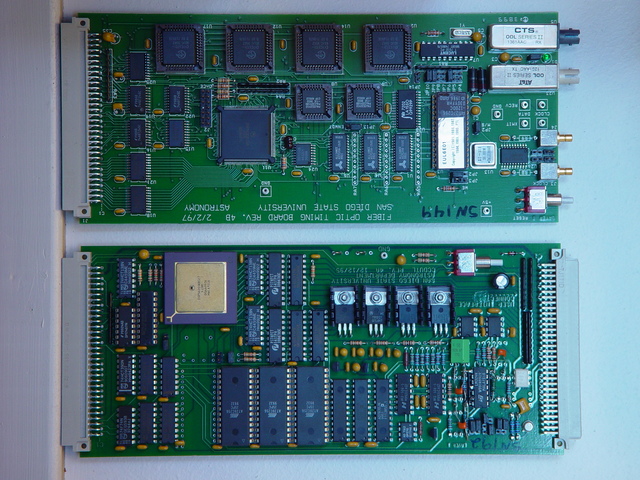

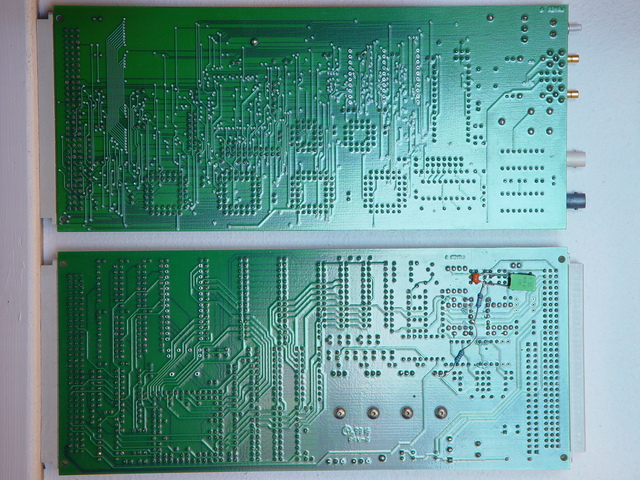

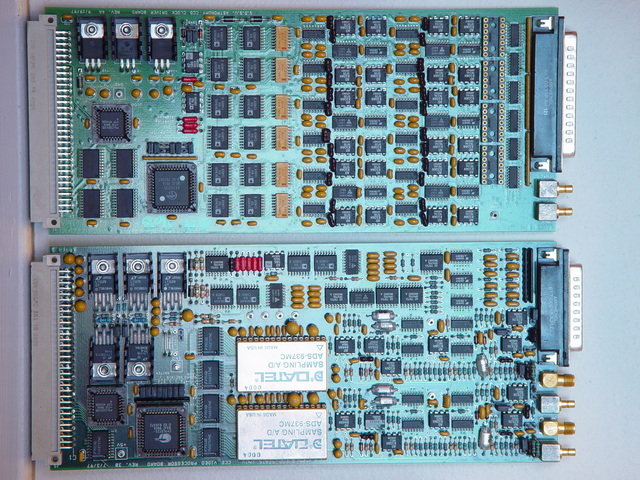

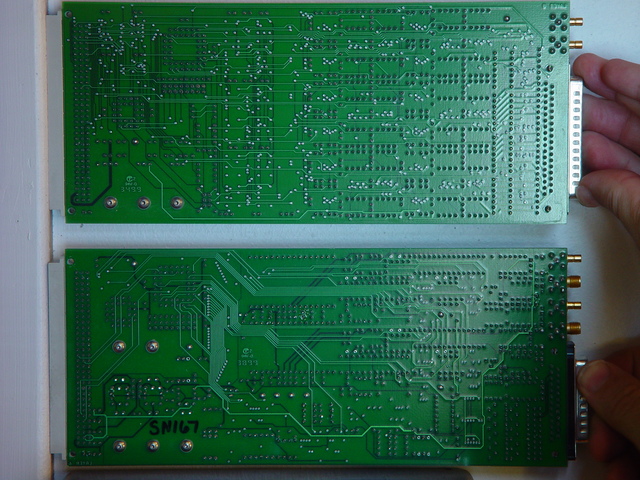

Photos of CCD boards

Click on the photos for the full resolution images.

Component view: timing board at the top, utility board at the bottom.

Solder side view: timing board at the top, utility board at the

bottom.

Component view: clock driver board at the top, video board at the

bottom.

Solder-side view: clock driver board at the top, video board at the

bottom.

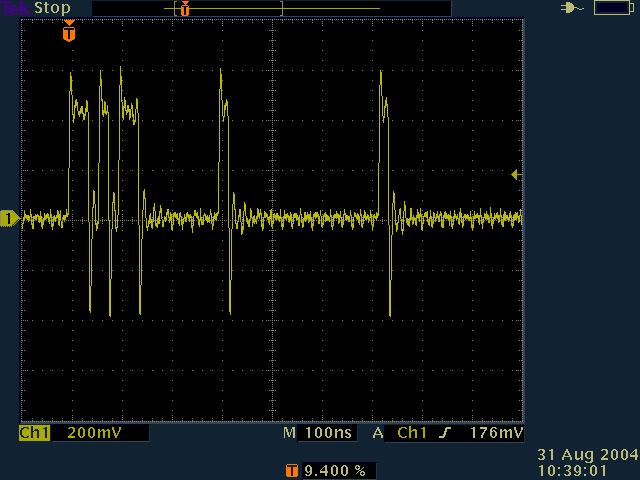

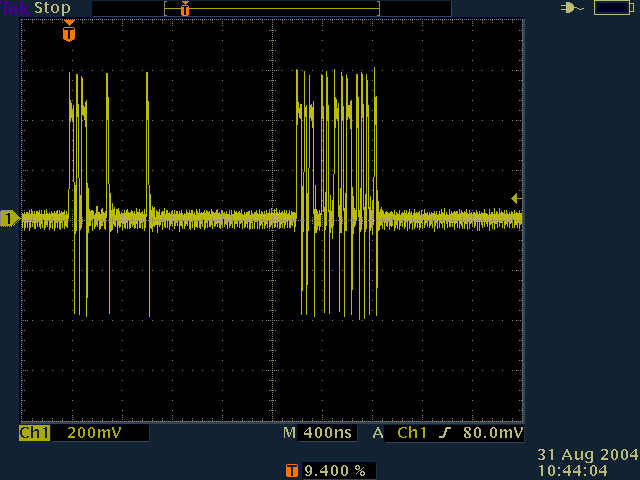

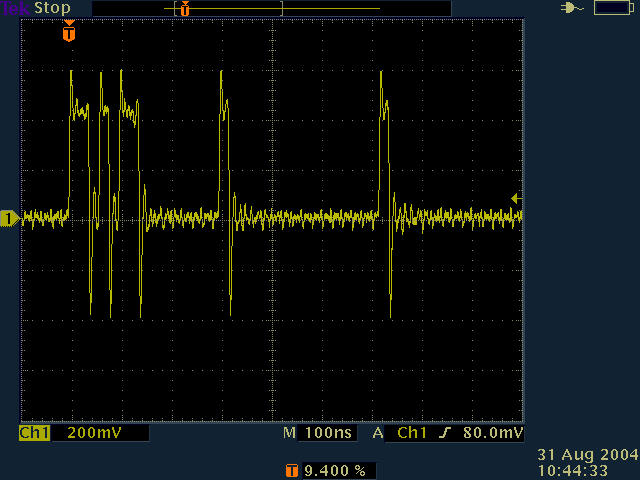

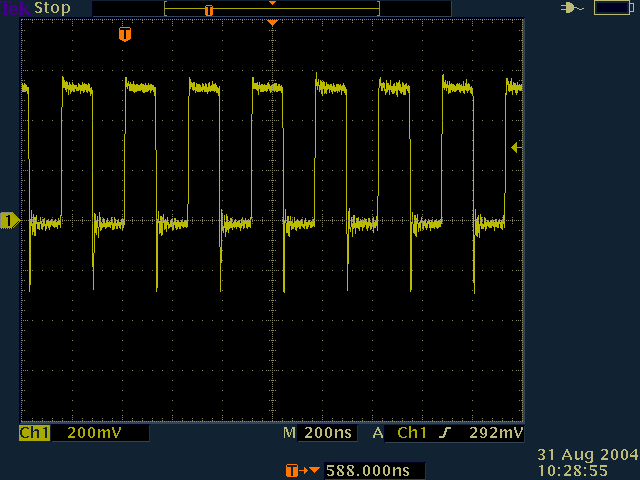

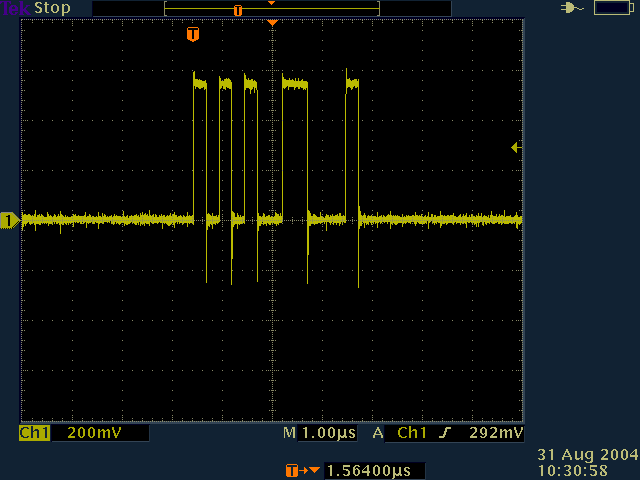

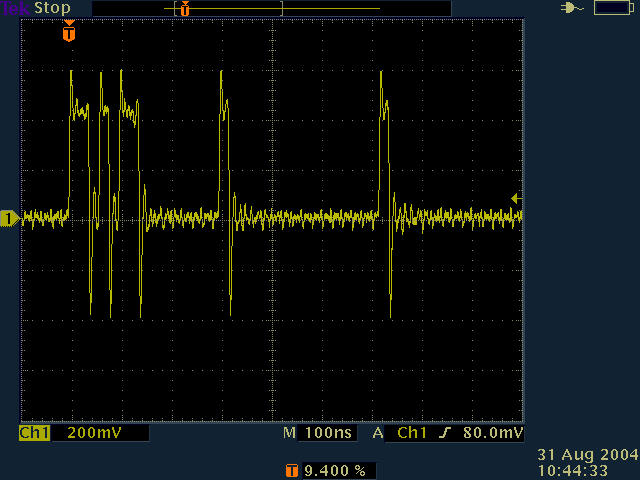

Camera oscilloscope traces

Bit patterns for status codes:

SYR 00 53 59 52 0000 0000 0101 0011 0101 1001 0101 0010

DON 00 44 4F 4E 0000 0000 0100 0100 0100 1111 0100 1110

ERR 00 45 52 52 0000 0000 0100 0101 0101 0010 0101 0010

RDR 00 52 44 52 0000 0000 0101 0010 0100 0100 0101 0010

TIMEOUT 54 4F 55 54 0101 0100 0100 1111 0101 0101 0101 0100

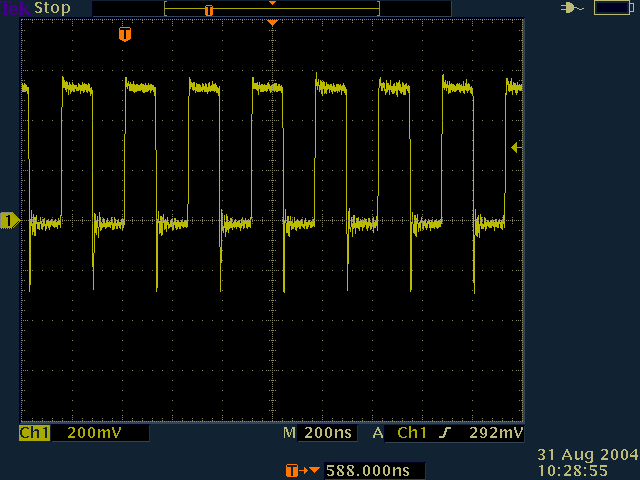

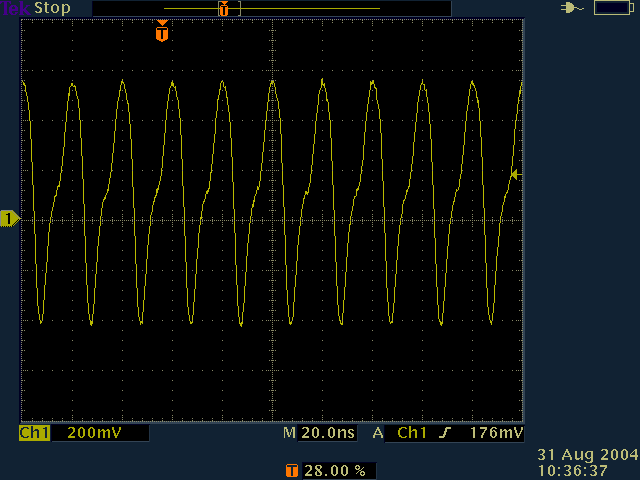

recv clock on timing board in gold box, 250ns period (4MHz):

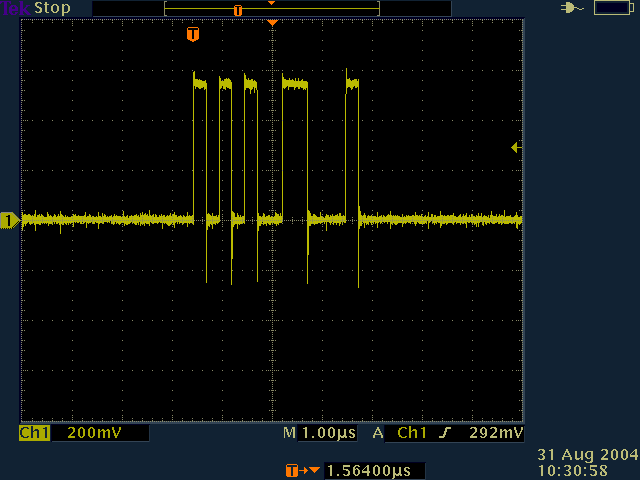

recv data on timing board, immediately after running the testcam

program:

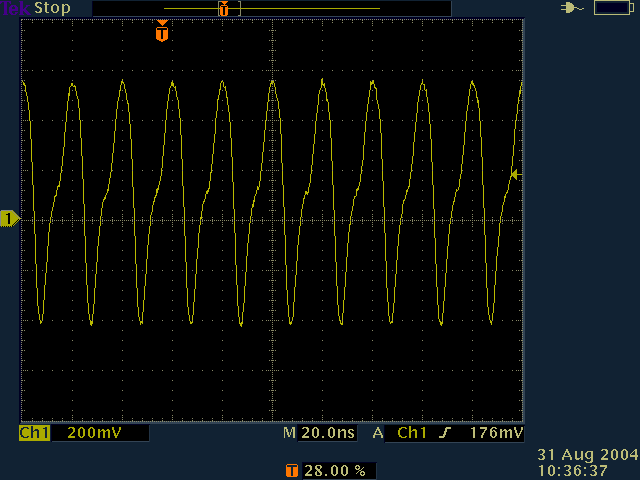

xmit clock on timing board (20nsec period, 50MHz):

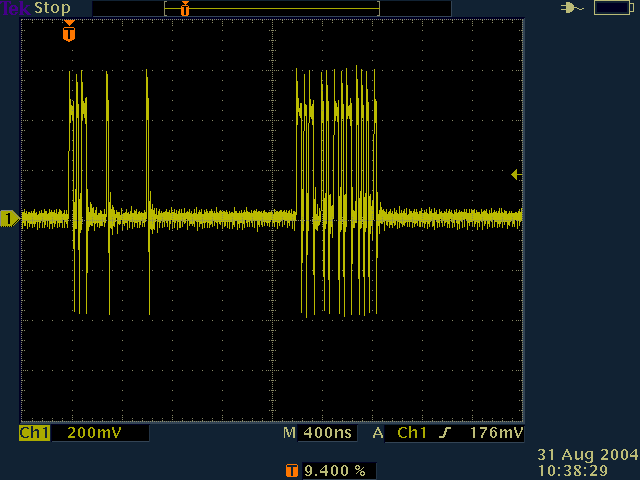

xmit data:

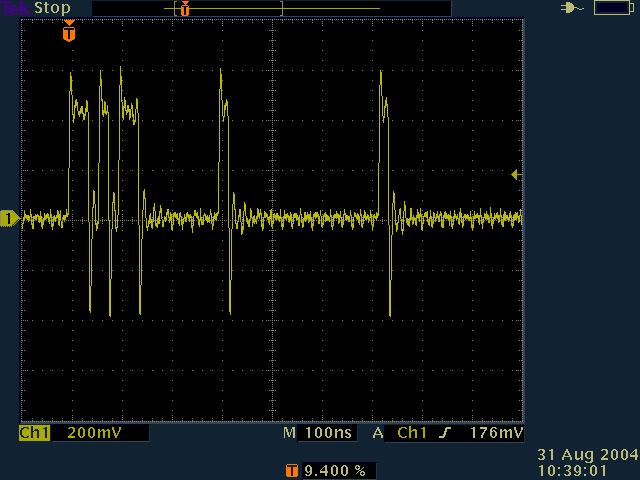

enlargement of previous trace:

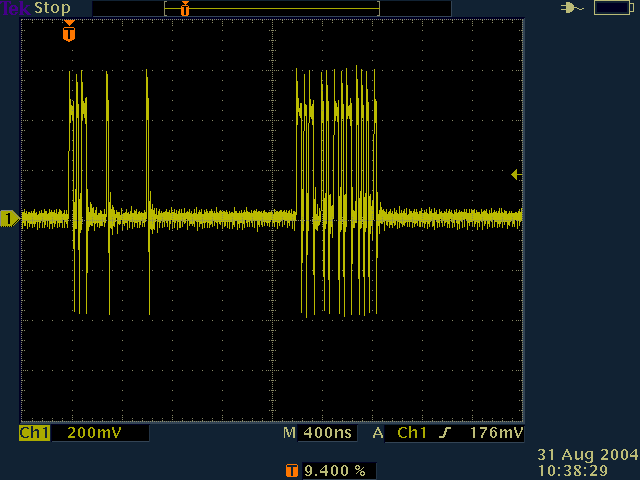

xmit data after pressing the reset button (which takes 0.7 seconds to

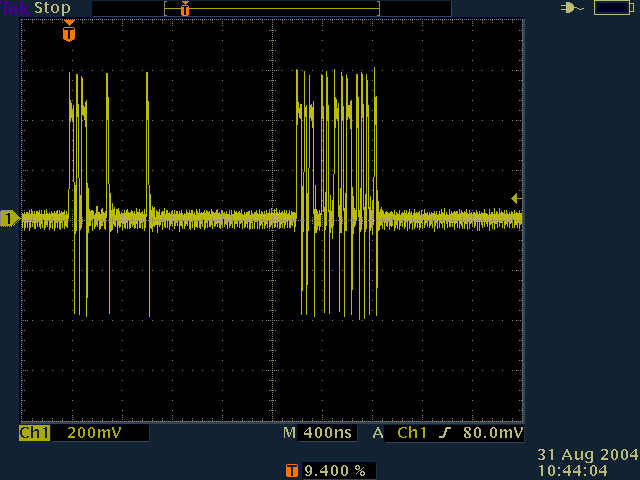

take effect):

enlargement of previous trace:

Mount computer

Analog, board 1

Channel 0 = RA

Channel 1 = Dec

Note: higher output numbers = lower output voltage +/- 10V

Encoder Card

Address: 0x20A

ICR: Valid index level will load the contents of the counter into the

Output Latch.

Active high index polarity.

Differential signals

10 MHz clock frequency

Counters not cascaded

Enable /BW (borrow) interrupt

Use IRQ 3

No wait state.

DIO Card, board 0

A0 - West Limit/ In

A1 - East Limit/ In

A2 - North Limit/ In

A3 - South Limit/ In

A4 - RA Amplifier Fault In

A5 - Dec Amplifier Fault In

A6 - E-Stop Tripped In

A7 - Dec Encoder Error In

C0 - RA Encoder Error In

B0 - RA Brake Out

B1 - Dec Brake Out

B2 - RA Heater Out

B3 - Dec Heater Out

Quick guide to rush

While not hardware as such, I'm including here a quick quide to some aspects

of rush, the Bourne-like shell that ROTSE uses.

rush is based on rc, an implementation of the Plan 9 shell for

UNIX. Authors are Byron Rakitzis and Tom Duff. See

here for

documentation.

Here are some examples of rush syntax:

rhelp # for help on ROTSE specific commands

path=($path /somewhere/else)

echo $path

lastFile=`{ls -t|head -1}

{sleep 60; echo Both commands run in the background}&

for(i in *.c){ls $i}

if(test -f /tmp/junk) echo /tmp/junk exists

while (){echo loop forever; sleep 10}

fn go { echo this is a function called go }

fn go # this deletes the function called go

rush reads the file ~/.rcrc at startup.

Processes that you start in rush are run as root.

Collimation of the secondary mirror

The secondary is flat, so only a tilt adjustment is necessary.

To assist with collimation, it is helpful to have an easy way to take

and display an image on the rotse computer. Here is one technique:

- Make sure that ds9, xpans, and xpaset are installed.

- Login as observer.

- Edit the ~/.rcrc file so that the path to ds9, xpans, and xpaset is

included in the command search path.

- Add the following functions to .rcrc:

fn minit {

# This function performs the initial setup, it should be

# run immediately after starting rush.

rinit

rmode manual

pgrep -f xpans > /dev/null || xpans -p 14285 &

pgrep -f ds9 > /dev/null || ds9 &

}

fn mdisp {

# Displays the most recent "junk" fits file.

f=`{ls -t /rotse/data/3a1/*_junk_*.fit | head -1}

xpaset -p ds9 file $f

}

fn mgo {

# Takes a 10 second exposure, and displays it.

rexpose -w -t 10 -n junk

sleep 3

mdisp

}

- Start up a couple of xterms as user observer. Run "rmonitor" in one

of them. Start the rotse system with "killrotse -nob; killrotse -nob

-dam; allrotse.pl". Wait until the clam is open and the mount is

synced and has moved to the zenith.

- Start "rush". Type "minit" to initialise. A ds9 window should open up.

- Type "mgo" to expose for 10 seconds and display the result. Sometimes

the most recent image isn't displayed - try "mdisp" to fix this. You might

like to use FRAME, NEW in ds9 to put new images into another FRAME for

comparison.

- Focus using, e.g., "fmove -r 3.65". Positions are absolute and in

millimetres, although the documentation says relative in microns.

- Offset the focus by -0.65mm. This should give nice donuts as per

the image below.

- Position the telescope for convenient access to the secondary mirror

micrometers. E.g., "rmove -w -r 5 0 0 -d -80 0 0", if the LST is "5 0 0"

and you are at Siding Spring.

- Call the lower left micrometer A, and the lower right one B.

- Turning A clockwise moves the "sweet spot" (where the donuts are

perfect annuli) on the CCD roughly diagonally from top right to bottom

left. Turning B clockwise moves the sweet spot roughly horizontally from

left to right. 1/16 of a turn is enough to move the spot by about 0.5 of

the width of the CCD.

- Iterate until the sweet spot is in the centre of the CCD, as per

the following image:

(click on the image for the full-resolution view)

Note how the hollows in the centres of the stars all point towards the centre

of the CCD. The final adjustments are perhaps 5 degrees of rotation of the

micrometers.

Here are some instructions from Fang Yuan on how to update the focus

model:

- After you aligned

the mirror and find a reasonable good focus position, you need to put that

position into the focus model file.

- First of all, you should delete the

/rotse/data/pipeline/prod/focus_update.dat, which is a small adjustment

from mini-focus run. Run "rhup schierd", so the original focus model is in

use.

- According to /rotse/run/etc/schierd.conf on 3a, the current focus model

file is /rotse/run/etc/focusmod_060726.dat. You

may copy this into a new file, and modify the entry in schierd.conf.

Because we are not changing the focus model, the only number has to be

changed is the constant term, which is now 3.64202. The trick is to find

out the offset between the current model and the new good focus, and add

the offset to the current constant. Say, for a certain pointing, the focus

model calculate 3.5, and you find it to be 3.7, then you should put

3.64+0.2=3.84 as the constant.

To get what focus the current model gives, just point with "rmove -r ra -d

dec" in rush, while "rmove -r ra -d dec -n" will just move the mount but

NOT the focus.

-

After you've changed the focus model file, "rhup schierd" again. Then you

may point again with "rmove -r ra -d dec" to see if the focus comes out

good. It just needs to be close enough to the best focus, and mini-focus

runs will take care of the fine tuning.

Replacement of the Dec encoder tape

Most of the following images expand if clicked on.

- Obtain a new piece of encoder tape, and borrow (if at all

possible) an encoder tape applicator (see image below). Cut the tape

to length with the supplied shears.

- Take off a side panel of the telescope

and release the focus cable from the Newport

controller box.

- Remove the top half of the telescope. It weighs perhaps 12kg, and

is an awkward, but possible, lift by one person. There aren't any

alignment pins, just unscrew the bolts and lift off, being

careful to clear the central optics tower. We lowered the

tube section over the side of the enclosure, but it is also possible to

lower it inside the enclosure.

- Attach weights to the telescope so that it is counterbalanced, and

can rotate freely through 360 degrees in declination. After this image

was taken, the optics were cleaned, and they came up perfectly.

- Remove the old tape by peeling it off, scraping the residual glue

with a sharp knife, and using a solvent (e.g., white gas, shellite,

Coleman fuel) to clean the disk. Then give the surface and the

surrounding area a thorough polish with 400 grade "wet and

dry". Finish with a careful clean with methylated spirits.

- Read the applicator instructions thoroughly. Attach the applicator

device

to the encoder mount. You will need to use the left-hand adaptor

plate.

- The following photo shows the applicator guide in position, with

the new tape ready to apply. Note that there is very little leeway,

and you have to be careful not to bend the tape through too small a

radius of curvature. Attach the tape to

the disk when the telescope is pointing directly at the north pole (or

south pole for Northern Hemisphere ROTSE's) - this is a place that the

telescope can never point to once the top half is

reattached. Carefully rotate the telescope through 360 degrees,

slowly, and in one direction only. After all the tape is on, remove

the applicator and use a lint-free cloth and firm finger pressure to

securely attach the tape from the outside to each end.

- Collimate the secondary.

Vaisalla precipitation detector

The Vaisalla precipitation detector is a model DRD11A. The sensor

surface should be periodically cleaned with pure water and a soft towel

(mild detergent is allowed). Avoid static damage to the sensor. The

pinouts are as follows:

Red

|

+12VDC +/- 10% @ 260mA max, 25mA

with

heater off

|

Blue

|

Rain ~ON/OFF open collector

output; grounded when rain detected; 50mA max

|

Green

|

Heater OFF input; ground to turn

heater on; float to turn heater on; heater draws between 0.5 and 2.3W

|

Yellow

|

Analog out; 3V when dry; as low

as 1V when wet

|

White

|

Frequency output; 1500Hz

to 6000Hz

|

Black

|

Ground for analog components

|

Brown (or clear)

|

Ground for heater

|

Odds and ends for ROTSE-IIIa

Our ethernet hub was purchased in January 2004, and is a

M-EZ6508TX 1 SMC 8 port

10/100 Switch

EZ6508TX

$50.00

Shipping address for data disks to Michigan

Carl Akerlof

450 Church Street

2477 Randall Laboratory

University of Michigan

Ann Arbor, Michigan 48109

USA

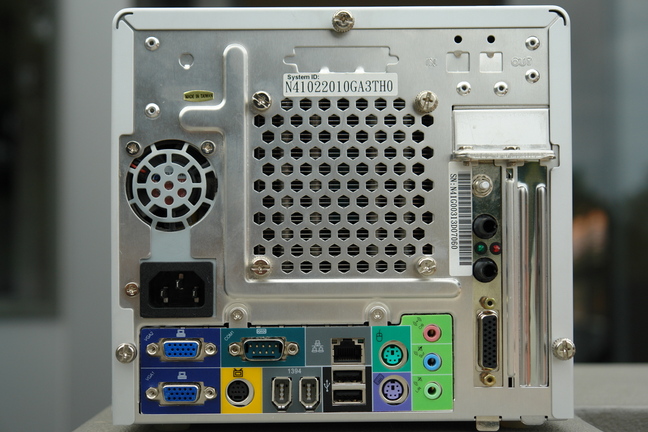

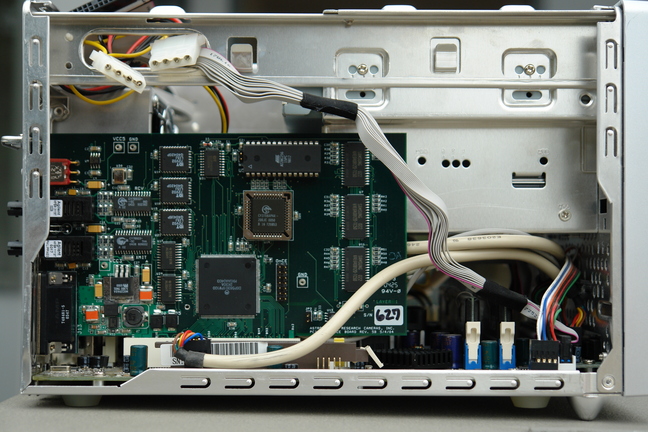

cam3a computer

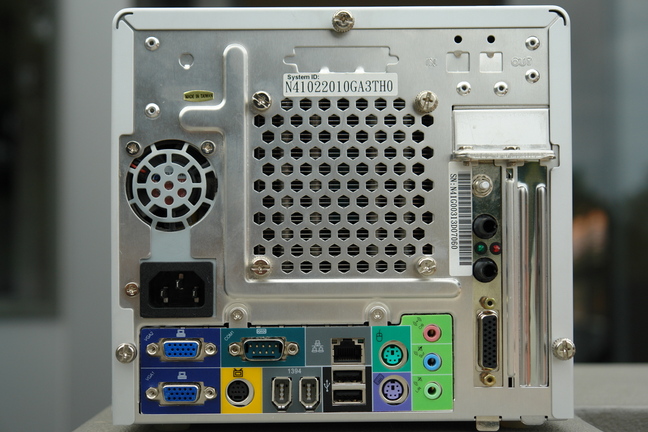

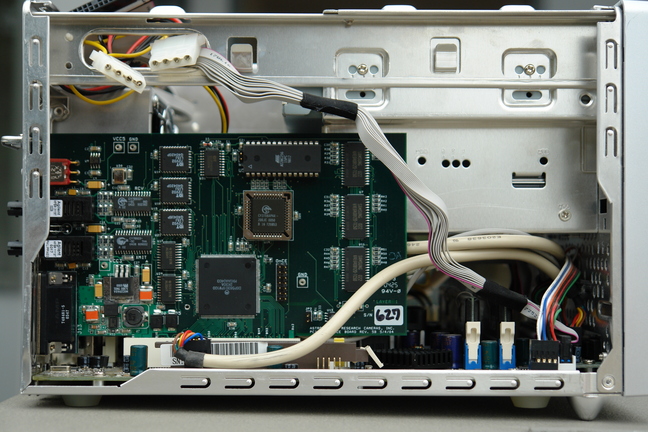

cam3a is a Shuttle SN41G2 "barebones" small-form-factor PC, serial

number N41G00313D07060, system ID N41022010GA3TH0. The motherboard is a

FN41 V2.0. The BIOS is fn41s032 dated 2005/5/23. The CPU is a 1.9GHz

Athlon. 1GB memory. 200GB Seagate hard disk. The chipset is an NVidia

nForce 2, which means you have to download NVidia drivers for the

network, sound, and graphics. We are currently running Linux 2.4.32,

with a Redhat 7.2 underlying OS.

Back view of cam3a:

Front view of cam3a:

Showing the CCD controller card. There is barely enough room:

With the case open: